Dec. 17, 2021

UCalgary research test demonstrates value of new carbon capture technology for large-scale industrial use

In the global race to roll back human impact on the climate, a research partnership between the University of Calgary and the gas separation industry has announced the game-changing results of a commercial test of a sponge-like new nanomaterial that captures carbon dioxide from flue gas on an industrial scale.

In the international journal Science, University of Calgary scientists and partner company Svante demonstrate the removal of up to 95 per cent of CO2 emitted from a cement manufacturing plant in Vancouver, B.C., dramatically scaling up and proving the value of technology a UCalgary group has been researching for eight years.

The novel sorbent material born in George Shimizu’s UCalgary lab is a highly refined version of a metal-organic framework (MOF), a class of super-adsorbent materials with growing research around the world for gas separation and storage. What distinguishes the UCalgary technology — known as Calgary Framework 20 or CALF-20 — is its unprecedented ability to capture CO2 on a large scale from a stream of gas containing water, says Dr. Shimizu, PhD, a professor whose lab in the Faculty of Science led the development of the chemistry behind the filtering compound.

“Since January, our material has been capturing one tonne of carbon dioxide a day — that’s a first for the MOF field,” says Shimizu. “As far as an industrial demonstration using MOFs, this is the very first demonstration in the world.”

Results have global impact for industry

The field results will be watched closely by large CO2 emitting industries such as Alberta’s energy industry, which is searching for commercially viable technologies to remove gases from emissions, reducing their CO2 footprint.

“Every type of gas stream with its own unique composition and temperatures and pressures poses a different problem,” Shimizu explains. The success of the demonstration opens a promising new path for industry. “It makes it less risky for someone else to want to try this novel material at an even bigger scale. It's really trailblazing a path for this entire class of compounds.”

The technology separates carbon dioxide in the flue gas generated by industries such as cement, steel, and oil and gas.

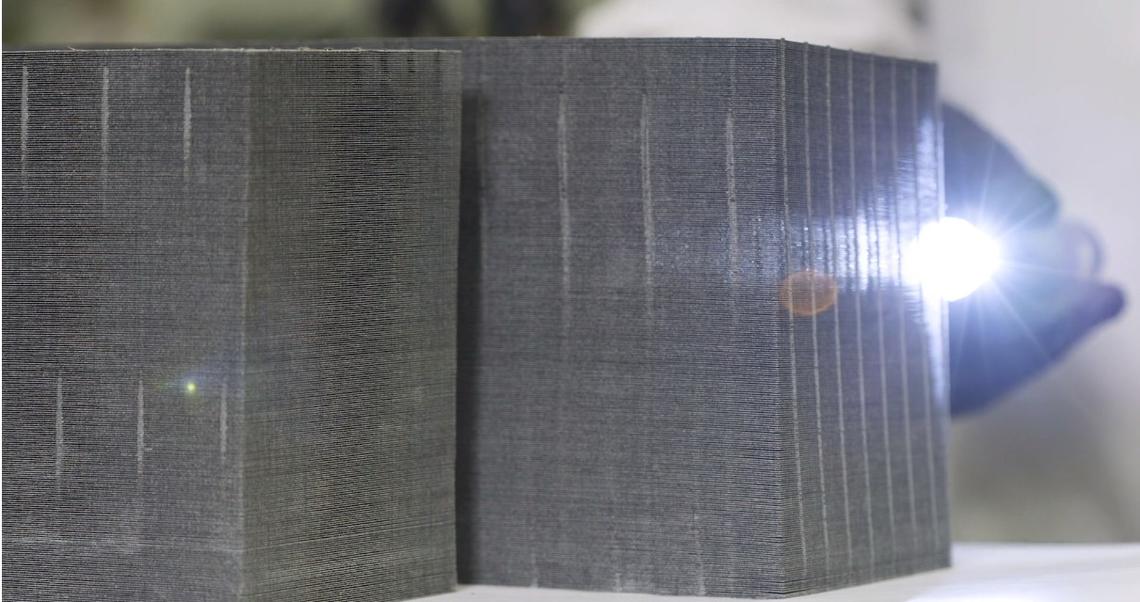

File photo courtesy Svante

Value of MOFs in gas separation

MOFs are highly porous materials made of metal ions and organic molecules or linkers. Actively studied for about 25 years, they can be tailored for a range of uses such as gas separation and storage, water capture, and drug delivery. In the Vancouver field test, CALF-20 was deployed in Svante’s proprietary structured adsorbent bed technology, creating a sponge-like filter that separates the CO2 first before extracting the water.

“For high-performance CO2 capture and removal, steam stripping — where you use direct contact of the sorbent with steam to flush out the CO2 — has been a sort of holy grail for the field. It is seen as the most effective way to do it,” says Claude Letourneau, president and CEO of Svante Inc. “This MOF material combined with our proprietary structured adsorption filter is a game-changer.”

In the Vancouver field test, the CO2 is sequestered and reused to improve the manufacture of concrete. In a parallel line of related research, Shimizu says his lab and other scientists around the world are actively exploring ways to reuse captured CO2 and other gases on a large scale for a range of new products, broadening the future application of MOFs in industry.

The scale-up of CALF-20 relied heavily on bringing together multidisciplinary expertise. “The exceptional nature of this material only becomes more apparent at higher levels of engineering testing,” Shimizu says. “And that was commercial scale equipment we didn't have.”

Academic-industry partnership drives results

Among UCalgary’s R&D partners are Dr. Arvind Rajendran, professor of chemical engineering at the University of Alberta; Dr. Tom Woo, UOttawa professor (and UCalgary alumnus) who models chemical processes at the atomic level; Svante, an industrial carbon capture solution provider using solid sorbent technology; and BASF SE, a multinational chemical company.

Carbon dioxide is trapped by Svante's proprietory filters, which are made with nanomaterials engineered with a high capacity for CO2 capture.

File photo courtesy Svante

The history of CALF-20 at UCalgary is incremental, collaborative, and entrepreneurial. Roger Mah and Jared Taylor, both co-authors of the Science paper, were two UCalgary student researchers in the Shimizu lab whose early contributions were critical to nurturing the scale-up from an academic curiosity to a product with industrial scope.

Dr. Mah, PhD’16, worked closely on the lab scale-up and led the technology transfer effort for CALF-20, as CEO of UCalgary spinoff ZoraMat Solutions from 2018 to 2021. “The team always knew that we were sitting on something special that had the potential to make a difference,” says Mah, who is now vice-president of research and development at Progressive Planet Solutions. “We wanted to see this material used in as many industries as possible, making an impact on emissions and ultimately climate change.”

Commercialization and spinoff

Dr. Taylor, PhD’12, is now employed as additives technology scientist for NOVA Chemicals Corp. As a student in the Shimizu lab, he focused on developing the lab-scale procedure at a gram scale and getting it to work at a kilogram scale, an increase of roughly 1,000 times. “It has a combination of physical properties that make it fantastic at capturing CO2, but moreover, it is simple from a synthetic standpoint and highly stable. I knew that if the material could be produced at scale and cheaply, it could be a game-changer.”

Shimizu reflects on the entrepreneurial thinking behind the project. “The very first part of an academic being entrepreneurial in mindset is realizing that there’s a goal beyond publication,” Shimizu says. “If you genuinely feel you have something that can solve a problem, that can help people, it's up to you to carry that baton forward.

“It’s not enough to just put research out there and think the mountain will come to you. There have been as many disappointments in this as successes. Ultimately, the successes have been big ones.”

George Shimizu

George Shimizu is a professor in the Department of Chemistry, Faculty of Science, and he leads the Shimizu MOF Group.

The CALF-20 project was supported by funding from Alberta Innovates Strategic Research Projects, the Collaborative Research and Training Experience program within the Natural Sciences and Engineering Research Council of Canada, Alberta GreenSTEM, Mitacs, Carbon Management Canada, the Global Research Initiative in Sustainable Low-Carbon Unconventional Resources at UCalgary, the Parex Resources Innovation Fellowship, and by Innovate Calgary’s licensing and commercialization services.

Roger Mah is a recent postdoctoral associate at UCalgary and a GreenSTEM fellow.